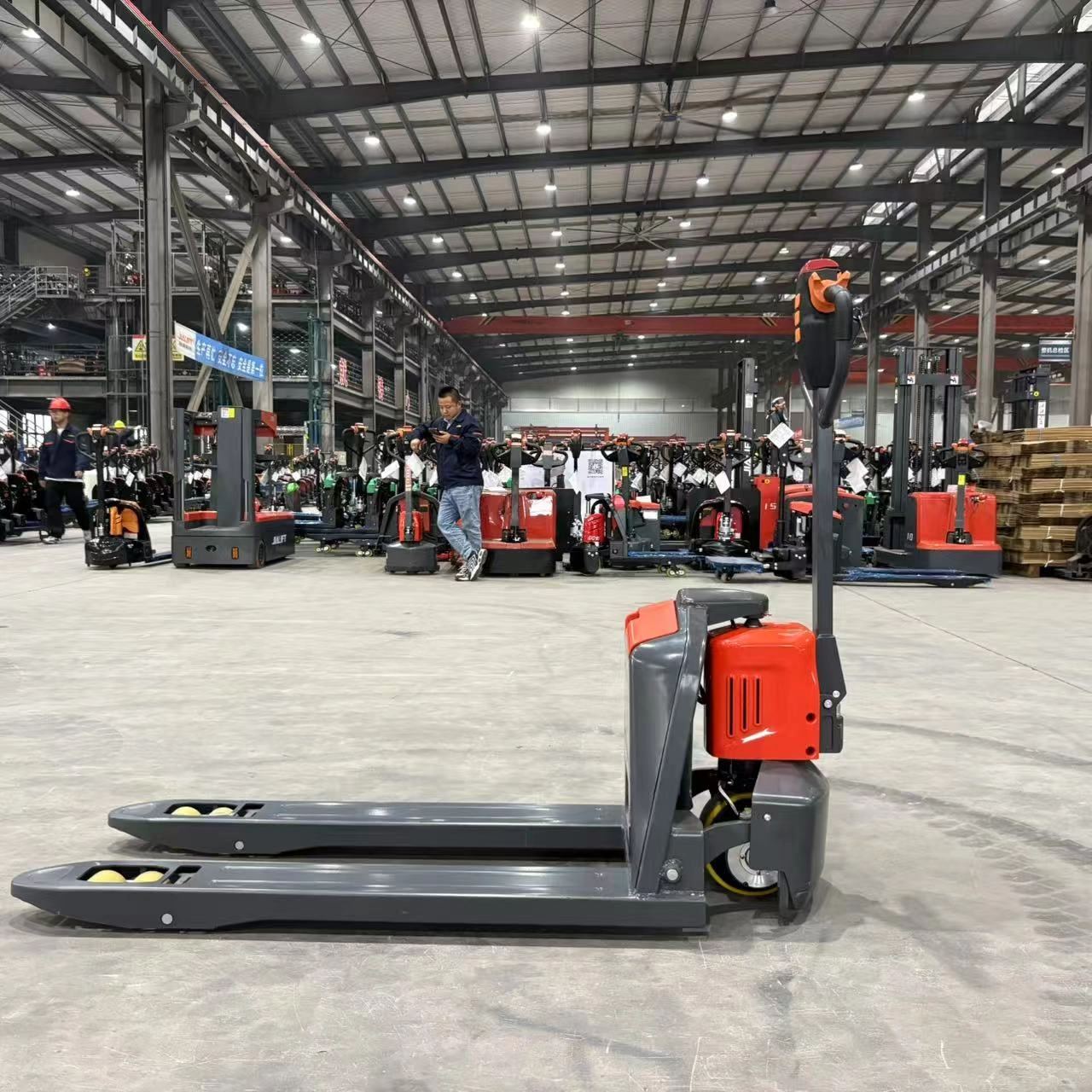

Electric Pallet Jack

Electric Pallet Jack, also known as an Electric Pallet Truck or Powered Pallet Jack, is a type of material handling equipment used to lift and move pallets over short distances within a warehouse or distribution center. It is a motorized version of a manual pallet jack, making it more efficient and less physically demanding to operate.

Key Features and Components of an Electric Pallet Jack:

- Electric Motor:The electric motor powers the pallet jack, allowing it to move without the operator needing to push or pull it manually. This provides more speed and reduces the physical effort required, making it ideal for handling heavy loads over longer distances or in environments with many stops.

- Forks:Similar to a manual pallet jack, an electric pallet jack has forks that slide under a pallet to lift and transport it. The lifting mechanism is powered by the electric motor, typically using hydraulics to raise and lower the forks.

- Controls:The operator controls the movement of the pallet jack using a handle with buttons or a throttle for forward/reverse movement. Many models also include controls for lifting and lowering the forks, usually via a button or joystick. The controls are usually ergonomic and easy to use for operators.

- Battery:Electric pallet jacks are powered by rechargeable batteries, typically lead-acid or lithium-ion. The battery allows the jack to run for several hours on a single charge, depending on the load and usage. Battery life can vary by model and usage intensity, and it can be recharged when necessary.

- Wheels and Steering:Electric pallet jacks are typically equipped with durable wheels made from polyurethane or rubber, designed for smooth movement on warehouse floors. The steering mechanism often includes a handle that allows the operator to easily navigate the truck, which is important when maneuvering in tight spaces.

- Load Capacity:The typical load capacity of an electric pallet jack ranges from 2,000 to 6,000 pounds (900 to 2,700 kg), though larger industrial models can handle even heavier loads.

Benefits of an Electric Pallet Jack:

- Reduced Physical Effort:Operators do not need to manually push or pull heavy loads, reducing strain and fatigue, especially in environments where pallets are frequently moved.

- Increased Efficiency:The motorized operation enables faster movement of goods over greater distances within a warehouse, improving overall productivity.

- Ease of Use:With simple controls, even operators with minimal training can use an electric pallet jack effectively.

- Better for Heavier Loads:Since it is motorized, it is ideal for lifting and transporting heavy pallets that would be difficult or impractical with a manual pallet jack.

- Compact Size:Electric pallet jacks are usually compact, making them well-suited for use in tight spaces, such as narrow aisles or confined warehouse areas.

Applications of Electric Pallet Jacks:

- Warehouses and Distribution Centers:For moving pallets from one location to another, loading/unloading trucks, and storing goods on shelves.

- Retail Environments:In stores or large retail spaces to move goods between storage and the sales floor.

- Manufacturing Plants:To transport materials or components across short distances within production areas.

- Cold Storage Facilities: Some models are designed for use in colder environments, such as refrigerated warehouses, with materials suited for those temperatures.

Types of Electric Pallet Jacks:

- Walkie Pallet Jacks:These are the most common type of electric pallet jacks. The operator walks behind the unit and controls it via a handle.

- Best for short distances and within tight spaces.

- Rider Pallet Jacks:These have a platform where the operator can stand or even sit while operating the unit.

- Suitable for longer distances and when the operator needs to travel across large warehouse spaces or distribution centers.

- High-Lift Pallet Jacks:These have a higher lifting capacity and can raise the pallet to a higher level, making them suitable for stacking items on higher shelves or racking systems.

- Useful for jobs requiring both lifting and transport functions in one machine.

Safety Considerations:

- Speed Control:Some electric pallet jacks include speed-limiting features to ensure safe operation, especially when navigating around obstacles or in crowded areas.

- Training:Operators should be trained in how to properly use an electric pallet jack to avoid accidents and injury.

- Weight Limits:Always adhere to the rated load capacity to avoid overloading the jack, which could cause damage or compromise safety.

Maintenance:

- Battery Care:Regular charging and proper maintenance of the battery are essential for maintaining the performance and lifespan of the electric pallet jack.

- Regular Inspections:It’s important to check the condition of the forks, hydraulic system, wheels, and steering to ensure smooth operation and avoid breakdowns.

- Cleaning:Keeping the unit clean, especially the wheels and lift mechanism, helps prevent dirt buildup and wear.

Common Questions About Electric Pallet Jacks:

How long does the battery last on an electric pallet jack?

The battery typically lasts for 4-8 hours of continuous use, but this can vary depending on factors like load weight, terrain, and battery type. Regular charging and maintenance can extend battery life.

Can electric pallet jacks be used on ramps?

Yes, many electric pallet jacks are designed to handle mild inclines, but it’s important to check the specifications of the model to ensure it is suitable for use on ramps or inclines.

Are electric pallet jacks better than manual pallet jacks?

Electric pallet jacks are more efficient and easier to operate, especially when moving heavy loads or navigating large areas. Manual pallet jacks, while simpler and less expensive, require more physical effort from the operator.