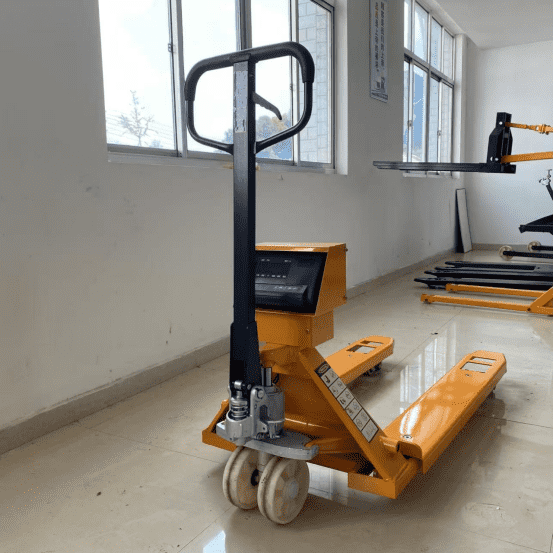

Pallet Jack Scale Description

A pallet jack scale is a type of pallet jack (also known as a pallet truck or hand truck) that integrates a weighing scale into the lifting forks. This allows the operator to weigh the load being carried without needing to move it to a separate scale, thus combining two tasks (lifting and weighing) into one efficient process. These devices are commonly used in warehouses, shipping and receiving areas, and logistics environments.

Here’s an overview of key points about pallet jack scales:

1. What is a pallet jack scale?

Answer: A pallet jack scale is a pallet truck equipped with a built-in weighing scale. It allows the operator to lift and transport pallets while simultaneously weighing the load, streamlining material handling processes. The scale is often located in the forks of the pallet jack.

2. How does a pallet jack scale work?

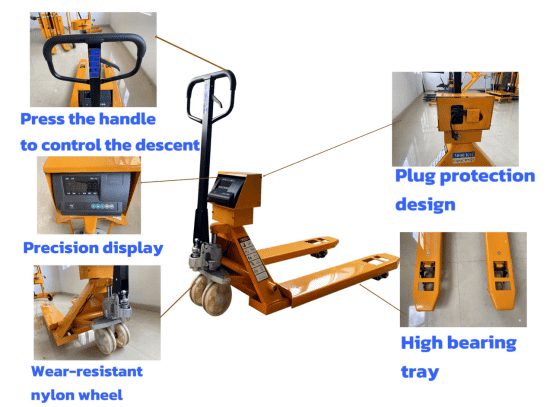

Answer: The pallet jack scale operates just like a traditional pallet jack to lift and move pallets, but it also includes load cells integrated into the forks to measure the weight of the load. When the operator lifts the pallet, the sensors within the pallet jack measure the weight and display it on a digital screen mounted on the handle.

3. What are the advantages of using a pallet jack scale?

Answer:

Increased Efficiency: It eliminates the need to move a pallet to a separate weighing station, reducing handling time and effort.

Cost Savings: Reduces the need for additional weighing equipment and labor associated with moving loads to a scale.

Accuracy: Provides precise weight measurements, often with an accuracy of up to ± 0.1% of the load.

Mobility: The weighing function is fully mobile, allowing operators to weigh loads anywhere in the warehouse or facility.

Improved Workflow: Helps prevent overloading of vehicles and containers by ensuring proper load weights during handling.

4. What are the typical features of a pallet jack scale?

Answer:

Digital display: Shows the weight of the load being carried.

Tare function: Allows operators to subtract the weight of containers or pallets to get the net weight of the load.

Built-in printer (optional): Some models include printers for printing weight tickets or labels.

Rechargeable battery: Most models are powered by a rechargeable battery for mobile operation.

Load capacity: Similar to standard pallet jacks, with typical capacities ranging from 4,000 to 6,000 lbs (1,800 to 2,700 kg).

Accuracy: The scale’s precision, typically accurate to within ±0.1 to 0.5% of the total load.

5. What industries commonly use pallet jack scales?

Answer: Pallet jack scales are widely used in industries where accurate weight measurement is critical during material handling, including:

Warehousing and logistics: For accurate shipping weights and inventory management.

Manufacturing: To weigh raw materials or finished goods.

Retail: For managing inventory and receiving deliveries.

Food and beverage: Where precise measurements are necessary for ingredients or packaging.

Pharmaceutical: To ensure accurate measurements of sensitive products.

6. How accurate are pallet jack scales?

Answer: Pallet jack scales are generally quite accurate, with most offering precision within ± 0.1% to ± 0.5% of the load’s total weight. However, the accuracy can vary depending on the model and the environment in which the pallet jack scale is used (e.g., uneven floors may affect measurements).

7. What maintenance is required for a pallet jack scale?

Answer:

Calibration: Periodic calibration is needed to ensure the scale remains accurate.

Battery maintenance: Recharge or replace the battery regularly to ensure consistent operation.

Cleaning: Keep the scale and load cells free from debris or obstructions that could affect the weighing function.

Inspection: Regularly check for mechanical wear on the forks and load cells, especially after handling heavy loads.

8. Can pallet jack scales print weight tickets or connect to software?

Answer: Yes, some pallet jack scales come equipped with built-in printers for printing weight tickets or labels. Additionally, more advanced models can connect to inventory management or warehouse management systems (WMS) via Bluetooth or Wi-Fi to automatically record weight data.

9. What is the cost of a pallet jack scale?

Answer: The cost of a pallet jack scale varies based on features, brand, and capacity. Basic models may start around $1,000 to $2,000, while more advanced models with additional features like printers, wireless connectivity, and higher accuracy can cost $3,000 to $5,000 or more.

10. What are the limitations of a pallet jack scale?

Answer:

Floor conditions: Uneven or rough surfaces can affect the accuracy of the weighing scale.

Weighing capacity: Limited by the lifting capacity of the pallet jack, typically around 4,000 to 6,000 lbs (1,800 to 2,700 kg).

Accuracy vs. fixed scales: While convenient, pallet jack scales may not be as accurate as fixed floor scales for very precise measurements.

11. How is a pallet jack scale powered?

Answer: Most pallet jack scales are powered by a rechargeable battery, providing mobility and allowing the operator to weigh loads without being tethered to a power outlet. The battery typically powers the digital scale and display, and battery life can last several hours or even a full shift, depending on usage.

12. Is a pallet jack scale easy to operate?

Answer: Yes, pallet jack scales are designed for ease of use. They operate similarly to a regular pallet jack, with the added function of a digital readout for the weight. Most models have a simple control panel for tare functions and basic weight recording.

13. How often should a pallet jack scale be calibrated?

Answer: The frequency of calibration depends on how frequently the scale is used and the level of accuracy required. For high-precision tasks, it is recommended to calibrate the scale once every few months or as specified by the manufacturer. Regular calibration ensures the accuracy of weight measurements.

In summary, a pallet jack scale is an efficient tool for facilities that require frequent movement and weighing of pallets, offering convenience, accuracy, and mobility all in one device.