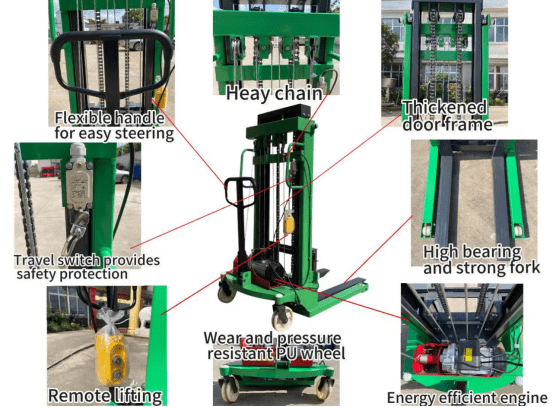

Electric Wire Rope Stacker Description

The electric wire rope stacker offers several advantages, especially in industrial and warehouse settings where heavy lifting, stacking, and material handling are required. Here are the key advantages:

1. High Load Capacity

Electric wire rope stackers can lift heavy loads, often ranging from 1 to 10 tons or more, making them suitable for industrial applications that require handling large and heavy materials.

2. Precision Control

The electric motor provides smooth, precise control over lifting and lowering operations. This precision helps operators handle delicate or valuable goods without damage, and the fine-tuned control reduces the risk of errors.

3. Increased Efficiency

The electrically powered lifting system allows faster lifting, lowering, and stacking compared to manual or hydraulic stackers. This leads to higher productivity in workplaces where time-sensitive tasks are essential.

4. Low Maintenance

Compared to hydraulic systems, electric wire rope stackers require less frequent maintenance. Wire ropes and electric motors typically have fewer moving parts that can wear down, reducing downtime for repairs and maintenance costs.

5. Durability

Wire ropes used in these stackers are generally made of high-strength materials, making them highly durable and long-lasting even in heavy-duty operations. They can endure repetitive cycles of lifting and lowering without significant wear.

6. Smooth and Safe Operation

The electric system allows for smooth movement and operation, reducing jerky motions that can lead to load shifts or accidents. This contributes to a safer working environment, especially when handling heavy or awkwardly shaped loads.

7. Compact Design

Electric wire rope stackers are often more compact than hydraulic stackers, making them ideal for use in confined spaces like narrow warehouse aisles or manufacturing facilities with limited room for maneuvering.

8. Energy Efficiency

Since they are powered by electricity, these stackers are often more energy-efficient compared to fuel-powered lifting equipment. This leads to lower operational costs, particularly in facilities where they are used extensively.

9. Versatility

Electric wire rope stackers can be used for a wide variety of tasks, such as lifting, lowering, stacking, and transporting different types of loads, including pallets, crates, and heavy machinery. They can be used in industries ranging from warehousing and logistics to manufacturing and construction.

10. Enhanced Safety Features

Many electric wire rope stackers come with built-in safety features like emergency stop buttons, overload protection, limit switches, and braking systems. These features help prevent accidents and protect both operators and the equipment.

11. Quieter Operation

Electric motors are generally quieter than hydraulic pumps or internal combustion engines, contributing to a more pleasant and less disruptive work environment, especially in indoor or enclosed spaces.

12. Environmentally Friendly

Since electric wire rope stackers don’t rely on fossil fuels, they produce zero emissions at the point of use. This makes them an environmentally friendly option for companies looking to reduce their carbon footprint and meet sustainability goals.

13. Reduced Operator Fatigue

The electric operation minimizes the physical effort required by operators. This is especially beneficial for tasks involving heavy lifting or repetitive stacking, reducing the risk of strain or injury.

In summary, electric wire rope stackers offer a blend of power, precision, and safety, making them ideal for industrial environments where high-capacity, reliable, and efficient material handling is essential.